Your cart is currently empty!

RevTech Nut Pasteurization

Over the last 15 years, a series of recalls has plagued the entire nut industry from the almond to the pistachio industries. A common link to each of these recalls. These recalls show that salmonella contamination was the reason for many of the outbreaks. Scientists and researchers found products that had not undergone the nut pasteurization process.

What is Nut Pasteurization and Why is it Important?

Salmonella can cause stomach cramps, diarrhea, nausea, headache, fever, and chills. In children and the elderly, this bacteria can compromise immune systems. For those exposed, antibiotics are sometimes needed to fully treat the bacteria.

In 2004, a salmonella outbreak in almonds caused 25 people to become ill, and the blame ended up being placed on 13 million pounds of compromised almonds. Due to major liabilities and financial losses, it became clear that the nut industry needed to do something to address the ongoing problem.

Almonds Take the Spotlight

The largest offender in the nut family when it comes to bacterial contamination and the potential for outbreaks is the almond. Almonds spend 8-10 days on the ground to dry after being shaken from their tree. Spending this amount of time on the ground exposes the almond to everything the earth has to offer. From your run-of-the-mill dirt and grime to animal waste. If you wouldn’t eat your food directly off the forest floor, eating raw almonds becomes a bit less appealing.

In the mid-2000s, it became clear that nut products, specifically almonds, were causing problems with consumers. Restrictions were then put in place to keep everyone safe. This is how the industry began seriously looking into making nut pasteurization the industry standard. Thus, decreasing outbreaks and therefore the potential for liabilities and product recalls.

California and Almond Pasteurization

California is the world’s largest producer of almonds by far. Once the public health crisis began tracing back to almonds, the regulatory board of almonds in California took action.

Their motivation was the health of consumers worldwide, but also to protect this crucial crop and its impact on the economy. In 2004, the Almond Board of California called for the pasteurization of California almonds. In 2007 the USDA finally passed the requirement. This led to almond growers throughout the country pasteurizing their raw almond products, before they hit the shelves.

Financial restructuring in the nut industry after the salmonella outbreaks was fairly remarkable. In the almond industry alone, about 4 million dollars was spent to improve manufacturing practices. This sparked the transition that would later become standard for each pasteurization process.

Bacteria That Nut Pasteurization Addresses

Due to Revtech and other pasteurization companies, consumers no longer need to consider safety when consuming ‘raw’ nut products. Store-bought raw nuts in America have always gone through the pasteurization process.

By coking these nuts they become safe. Therefore, pasteurization is not important. The cooking process will help kill off any harmful bacteria on the nuts. Pasteurization requirements from the government do not anticipate if chefs are going to cook their nuts or not.

It would be impossible to estimate how many nuts will be eaten raw or cooked. It is important to make sure the raw nuts have the least risk of contaminants possible. Nut pasteurization kills harmful bacteria, making raw nuts safe to eat and avoid any contamination issues. Salmonella is the bacteria that Scientists and Doctors consider the biggest risk for the food industry in the recent era.

RevTech: A Leader in Nut Pasteurization Technology

Since its creation in 1997 by founder Martin Mitzkat, Revtech has been an industry leader. A leader in both the design and fabrication portion of pasteurization technology all over the world. Revtech is a French company using steam pasteurization to protect against health risks associated with eating untreated nuts. In April of 2013, they successfully became the largest certified almond pasteurization system in the world at a factory called Almond o Australia.

RevTech has an intense commitment to quality and offers unique technology to help customers develop exciting projects. According to the company, each project receives an analysis from an individual-centric approach. A dedicated team of engineers and technicians uses the machine to ensure maximum results and innovation.

In a world where being environmentally conscious is important, Revtech is at the front of the pack. For over 20 years, they’ve focused on creating technology with low energy requirements. They’ve applied this knowledge successfully with over 120 companies. A leader in the pasteurization and food industry, Revtech also specializes in drying and roasting nuts.

Revtech’s Methods of Nut Pasteurization

The first method of nut pasteurization, which Revtech regularly employs, is called steam pasteurization. During this process, flash heating using natural water steam kills bacteria. The machine exposes the nuts to steam for eight seconds at temperatures between 210 to 215 degrees Fahrenheit. For 44 seconds, they then fall through a high-heat dehydration tunnel to remove any moisture resulting from the steam. The circulating air temperature at this time is between 391 to 395 degrees Fahrenheit. This process will not change the taste of nuts and is proven to eliminate harmful bacteria successfully.

Another method of making nuts safe is by roasting the nuts, but this changes both the properties and appearance of the nuts. During this process, hot air temperatures heat nuts to take away any bacteria and tend to oxidize them. This can shorten their shelf life. This is why nuts generally do better when a two-step roasting process is employed to stabilize the microstructure of the nut and generate the desired color and flavor.

What is Blanching?

Another tactic employed is blanching. With this, they remove the skin of the nut and put it in hot water. Blanching is a multi-step process whereby a nut is scalded in hot water, and then immediately dipped in cold water. This makes the skin fall off the nut very easily. The nut and skin go through a roller in the factory to separate them. Then drying the nut is on a conveyor belt using a specially designed oven.

Sometimes nuts are fumigated for bacteria in the final step of nut pasteurization used by Revtech, which is propylene oxide pasteurization. Propylene oxide is a registered fumigant in the United States for the reduction of bacteria, yeasts, and mold on raw nut meats. Typically, the procedure is done at over 86 degrees Fahrenheit and has been in regulation standards with the FDA since 2004.

Revtech’s Nut Pasteurization Technology and Process

A recent talk given to the Nut Growers Association by Celia Schlosser of RevTech addressed what the company does for the Industry. Both the technology and how it finds use in nut pasteurization are detailed.

For proper pasteurization of a product, the temperatures must exceed 180 degrees Fahrenheit. This is a process that requires several steps. Revtech’s temperatures slightly exceed that amount of heat to make sure these pasteurized nuts are using their technology to assure every nut is safe in the end. From the base of the tower, a preheating stage completes before every pasteurization process.

The Revtech Pasteurization Technology

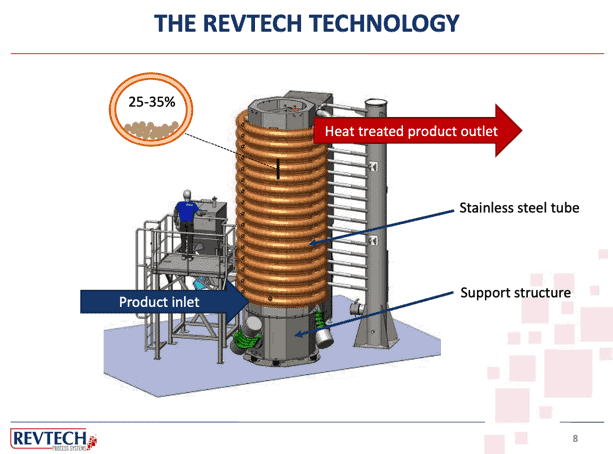

The Revtech pasteurization technology is based on a heating tower, which serves as the support structure. A stainless steel tube is then run and coils around that support structure. The ingredients, which in this case are nuts, face high heat and distribute throughout the tube from the bottom to the top.

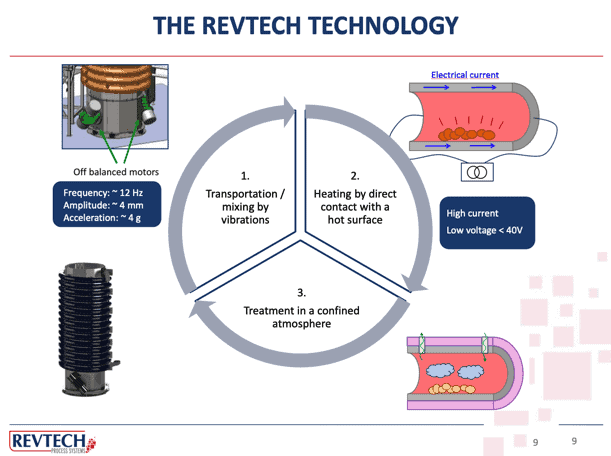

There are three basic steps when applying sterilization techniques to the products through the pasteurization system. The first step is the mixing of the nuts and transporting them by vibration. Two off-balance motors create vibration at the base of the structure. This allows the product to move from the bottom to the top.

The second step is direct heat by coming into contact with a hot surface. This is achieved through an electrical current running to the tube of the structure. Finally, hot air or steam is injected into the product in a confined atmosphere, helping to reduce the micro load in each batch of nuts.

When the product leaves the pasteurizing machine, it then passes through a drying spiral. It is through the vibration that the product is dried completely. Cool air is blown onto the product in order to cool it off for storage, packaging, and shipment. Thanks to the pasteurization process, these nuts could then be directly (and safely) placed into the palm of hungry snackers.

Product Appearance

Revtech’s process of steam pasteurization does not change the appearance or texture of the product. When looking at one nut that has been through the process and one that has not, it is almost impossible to tell the difference.

It should be known that almonds in the United States may have the label “raw” even when they have been through the pasteurization process. You can tell the difference between pasteurized and raw nuts by soaking them in water. Pasteurized almonds will not sprout when soaked in water and will grow moldy over time. Other raw nuts are great for soaking, as they release various beneficial chemicals from the process.

The Steam Pasteurization Process

Are all nuts in the U.S. pasteurized? The answer is complicated. Many of the commercial companies using this equipment are not under legal requirements to engage in pasteurization. They are likely to have gone through pasteurization because they are more desirable to big retailers. This is due specifically to keeping shelf life for a longer period of time.

Steam is added to each batch of nuts before their pasteurization. The packing and storing come directly after finishing this process. Many businesses say that they use this equipment in order to increase their profit. If pasteurization is not a requirement under current guidelines, then it is useful to think in terms of increasing shelf life.

Benefits of Pasteurization

After nuts have to go through pasteurization, they can stay fresh for at least six months. Only when stored in airtight containers and kept in cool, dark places. In this way, it can save consumers money. When nuts receive treatment correctly, they will have a greater shelf life.

Only when they want to change the properties, texture, or taste does Revtech engage in the roasting of nuts. To achieve this, Revtech simply adjusts the temperature in the tube of the same machine, increasing the time the nuts require processing. This decreases the moisture in the product and further develops the taste and color. The process of roasting only takes slightly longer than pasteurization. The steaming process includes oil during the roasting process.

The Research on Pasteurization

Pasteurization has been scientifically shown to have very little effect on nutrients found in nuts. Those ingesting pasteurized nuts will still get the vitamins and nutrients they are looking for in these products.

A quote from the U.S. Food and Drug Administration says that the loss of nutritional benefits from pasteurizing nuts is very small. It certainly does not outweigh the risks involved in not protecting against many dangerous bacteria and pathogens.

Revtech’s Global Reach

Currently, RevTech has over 120 projects installed in multiple factories all over the globe. They mostly work with nuts and various kinds of cereals, including wheat, corn, and barley. In addition to these initiatives, they also work with the pasteurization of herbs and spices. This business is particularly growing in India. In the United States and Canada, Revtech’s work extends to deal mostly with almonds and peanuts, as well as, seeds.

Many large companies install multiple units of RevTech’s machinery for both pasteurization and roasting. Their equipment, many consider being some of the most expensive on the market. This is a customer perception that holds balance with their reputation at the forefront of food safety, distribution, and processing. RevTech wants to work with the largest of the large worldwide companies. They do have small systems for small business customers. Revtech is also open to relationships with cooperatives and all kinds of different farmers who wish to create clean products.

Patent-protecting innovations come from a wealth of experience in design. Revtech is a company that has a devotion to pushing the envelope in design. They continue to develop excellence in heat treatment and pasteurization for a host of nuts and other dry ingredients.

As regulations change and consumers become more educated, it is important that companies remain transparent about their processes. Customers need to know that there is a commitment to keeping bacteria out of food sources. Revtech’s innovative, eco-friendly, and health-conscious initiatives are a prime example of a company with values.

-5.jpg)