Your cart is currently empty!

Transporting Bananas | Farm To Plate Banana Transport System

Bananas were not a plantation or export crop during the colonial era in the Caribbean and Central America, mainly because of the difficulty of transporting them to distant markets. Although bananas found a ready market in schooner days, they remained a luxury item until the introduction of steamships, the extension of the railroad throughout the United States, and the availability of refrigeration. These innovations made it possible to cut the transit time and keep the fruit at a constant temperature to slow the ripening process.

Bananas entered North American markets and became important in the culture and diet of the United States partly due to the transportation revolution that began in the latter part of the nineteenth century. Beginning with the railroads quickly followed by steamships, trucking, and eventually an interstate road system, Americans spread out across an immense continent while remaining connected with the cities and ports on the East and West coasts. Mail-order catalogs and a growing wholesale and retail network meant that the goods enjoyed in one area of the country were soon available to all.

The first official banana importation was recorded in the United States in 1804 when the schooner Reynard brought thirty stalks of red bananas to New York from Cuba.’ Banana importing was a risky business for sailing vessels. Contrary winds or calm seas might extend the voyage length, and the fruit would ripen and rot before reaching East Coast ports such as Philadelphia, New York, and Boston. Ship captains and crews sometimes brought a few stalks on board for themselves, and if any of the remaining bananas reached port in salable condition, they might make a nice profit. Usually, they did not.

Sporadic Banana Importing

Sporadic attempts at banana importing during the mid-nineteenth century by American entrepreneurs brought small quantities of produce from independent growers in the Caribbean and Central America. In 1830, Capt. John Pearsall included fifteen hundred stalks of bananas in the cargo of the Harriet Smith.” Pearsall is credited with being the first to risk bringing a full cargo of bananas to the port of New York. These may be the bananas that James Fenimore Cooper referred to when he reported that “bananas” could be found in the New York market.

It was not until 1843 that official port records first listed bananas. That year, a commission merchant imported three hundred bunches of Cuban reds and sold the lot at twenty-five cents a finger, over two dollars apiece in today’s money. Some years later, the merchant was forced to declare bankruptcy when a shipment of three thousand bunches reached the port too ripe to sell.

By 1850, cargoes of Cuban bananas were being delivered to New York, Philadelphia, and Baltimore. Pushcart peddlers, waiting at the dock, bought a few bunches at a time, first come, first served. But besides these occasional small shipments to East Coast ports, bananas were virtually unknown in the United States before the Civil War.

As the banana trade increased, fruit import companies were formed to purchase bananas by the shipload. In the Caribbean islands, company representatives sent messengers to interior farms telling growers that a ship would reach a certain coastal site on a given day prepared to select and purchase bananas. The bananas were transported to the coast from the interior by river, canals, rail-road, or, when these were not available, on the heads of women. The product was left to accumulate until the steamer arrived.

Development Of Habors For Transporting Bananas

At first, there were few harbors in the banana-growing areas. Ships were anchored offshore, and the fruit was loaded onto small boats by men, women, and children who waded out to them carrying each stem of bananas overhead to avoid the salt water. The full boats were poled beyond the breakers to the anchored ship, and rope nets took up the bananas. Because of the perishability of the fruit, the growers were always in a hurry to sell, and the American merchants were able to keep prices low. The merchants, in turn, faced risks of heavy losses and fierce competition during the voyage to North American ports.

United Fruit was the first to achieve a constant, year-round flow of bananas to North American cities. The company created a refrigerated distribution network comparable to meatpackers and produced a truly national market. A 1904 United Fruit Company booklet noted that “the secret of success lies in having the fruit properly grown, cut at the right time, handled without bruising, bringing it into the Northern markets before the green fruit begins to color, and then distributing it immediately to consumers with every item of expense kept at the lowest point.”

United Fruits Success

United Fruit was so successful that it was accused of monopolistic practices by the American Banana Company. An investigation was launched by the Committee on Interstate Commerce of the United States Senate in 1908. In its defense, the United Fruit Company hinged on its only advantage, which is their equipment and organization. The defense is that their systems are imperfect and competitors can come around with a better system. They have substantial advantages, but they claim not to be a monopoly. Another corporation can own its plantations and adopt improved planting, cultivation, and handling methods.

The report to the Committee on Interstate Commerce concluded that:

“The operations of the United Fruit Company have so increased the market for bananas at all points, and have so organized the trade, that anyone introducing bananas at the seaboard finds a large independent market not at all bound to the United Fruit Company, and which is open to anyone who can deliver proper bananas at competitive prices.”

The committee accepted this argument. At most, The United Fruit Company owned 80% of the banana market. The company was not broken up due to monopolistic practices. Serious charges of monopolistic practices were again faced in the 1950s.

Banana Transportation At The Ports

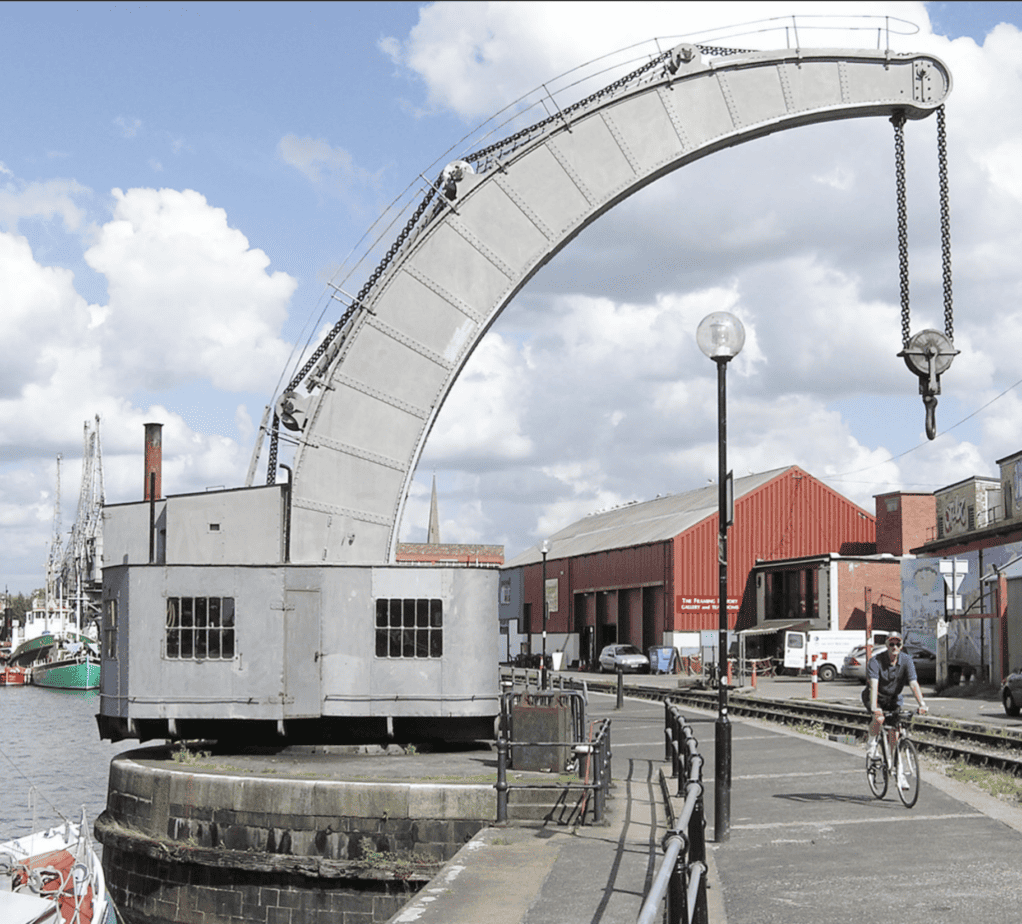

Initially, workers unloaded banana ships by carrying each 100- to 150-pound fruit stems out of the holds. A cargo of 35,000 stems took 400 laborers seven to eight hours to move from the ship to waiting railroad freight cars. The men stood in a long line extending from the ship’s interior to the waiting freight cars on the dock, and each stalk would be handed from man to man until it reached the appropriate car.

In 1903, the first unloading machine was introduced in Mobile, Alabama, and then in New Orleans. A circular chain dipped canvas buckets into the hold, where longshoremen placed one stem in each bucket to be lifted to the deck. The buckets could move 2,500 stems an hour, far faster than any number of men could carry the fruit, with big savings for the fruit companies. An electrically driven conveyor system was put into operation in Galveston, Texas. These are the electrically operated fruit conveyors. This was a time before containers became the normal sight at ports. The wharf would appear in the early 1900’s to be swarming with moving bunches of bananas set on boats.

One of the problems with this new machine of a steam crane was that it was too fast for human workers and could only be run for forty minutes every hour. By 1920, the conveyors were extended to a dockside monorail trolley system to reach the waiting freight cars, and the fruit was transferred almost without human handling. The new system saved three hours per ship and displaced at least 400 jobs at a cost savings of 2.5 cents a stalk. The total annual savings were estimated not to miss the million mark greatly.

Handling Winter Weather

During winter weather, operators warmed up the fruit several degrees in the ship’s hold before unloading. They also sheltered the unloading machines with canvas canopies to protect the fruit from the cold. On the dock, automatic tally machines counted each stem. Workers load the bananas onto railroad cars and trucks. Local sales at reduced prices include damaged fruit. They also included too ripe of fruit.

Most fruit companies chartered or leased ships built in Europe from Norwegian or British owners specifically for the banana trade. In 1900, United Fruit out of Boston had thirty-six steamers built in these countries. Twenty ships worked out of Boston, New York, Philadelphia, and Baltimore ports. The “Southern Fleet,” so called because it carried fruit to New Orleans and Mobile. Another 21 ships operated along the Pacific coast. By 1915, United Fruit was operating a fleet of ninety-five ships. The ships had 5,000-ton capacities, carrying 40,000 bunches of bananas each trip. The invention of dried sweetened banana chips allowed for a more hardy product in winter weather.

The First Refrigerated Produce Boat

The S.S. Venus, the first refrigerated produce boat, was launched in 1903. That year, United Fruit Company imported 1¼ billion pounds of bananas from its Caribbean holdings. By 1905, banana imports reached 33 million bunches, over 3½ billion pieces of fruit, an average of 40 bananas a year for each person in the United States.

Ships Carrying Bananas And People

By 1920, United Fruit had become one of the largest enterprises in the United States, with a vertically integrated network of plantations, refrigerated steamships, and railroad cars to produce, transport, distribute, and market bananas. Besides bananas, the Great White Fleet carried passengers, mail, and other merchandise between Caribbean and North American ports. A second fleet, painted gray, operated between the Caribbean and Europe. Banana ships carried freight and mail on return trips to the Caribbean using otherwise empty cargo space. Many of these ships were equipped with comfortable passenger cabins, and the service rivaled that of the transcontinental railroads.

In 1902, over 5,500 people chose to travel on the banana boats. A 1904 publication described United Fruit’s steamship passenger service. One vessel called the “Admiral” was a steamship operated by this United Fruit and praised for being American-built. Adapted to tropical travel. They have roomy promenade decks, cool and airy, and well-ventilated staterooms on the main deck.

The dining saloon is on the main deck, opposite the engine room. Bathrooms are supplied with fresh or sea water and are at the disposal of passengers at all times. The table is set with every delicacy of the northern and tropical markets. The ships are furnished throughout with a perfect system of electric lighting and steam heating. Finally, The stewards and waiters are unremitting in their duties. Everything is done for the comfort and convenience of the passengers.

United Fruit Opens Hotels For Business And Pleasure

The company also built hotels in Jamaica and other popular destinations. United Fruit promoted tourism and established a separate passenger department featuring special tropical cruises. They published travel guides such as “A Happy Month in Jamaica” (c. 1915), in which potential tourists or armchair travelers could look at lots of black-and-white photographs and read descriptions of what to see and where to stay. Concerns about foreign travel were soothed with assurances that disembarkation at the wharf of a modern American hotel was conducted in the best American method. On landing in the Carribean, greedy native porters do not snatch our baggage and quarrel about the fees. The fare from Boston, New York, or Philadelphia to Port Antonio (including meals and berth in stateroom) was $40 one way and $75 round trip. Fares were $35 and $70 from Baltimore.

The Great White Fleets Origin For Transporting Bananas

In 1918, noters provided businessmen assurances that the accommodations and cuisine on the ships of the Great White Fleet would match the standards of their favorite club or hotel. The promoters promised businessmen that they could enjoy the freedom of the salt air, sunshine, and relaxation of a sea voyage without the petty annoyances caused by inferior quarters or service.

These assurances aimed to provide a comfortable and enjoyable experience for the businessmen traveling on the Great White Fleet. A travelogue for a “Great White Fleet Caribbean Cruise” published in 1922 gave a highly romantic account of the various ports of call including Cuba, Jamaica, Panama, Costa Rica, Colombia, and Guatemalan. Potential customers were assured that the steamships are all specially designed for cruising in the Caribbean Sea, and while some are a little larger than others, the same high standard of service is aimed at all. They are the most expensively constructed vessels of their kind in the world. All cruise staterooms are outside and are first class only.

Not how large, but how fine, best expresses the thought dominating the construction of the ships of the Great White Fleet, a steamship service designed to meet the most exacting requirements of the traveler.

The History Of The Great White Fleet

In 1928, at the height of its success, the Great White Fleet numbered a hundred vessels and carried 70,000 passengers, 250,000 bags of mail, and 56 million stems of bananas.

Standard Fruit entered the tourist business in 1926, serving New Orleans to the Caribbean. In the early 1930s, Standard Fruit competed with United Fruit for the banana trade in Central America and the tourist trade in North America. Standard offered twelve-day cruise service to Nassau and Kingston from New York and package tours to Cuba, Mexico, and Honduras.

At the height of the Depression, United Fruit Company advertised its 30th Successful Season. Guest cruises to the West Indies and Caribbean with outdoor swimming pools and other modern shipboard facilities.Advertising cruises with superb cooking that helped make these ships famous and with adept staff.

The cost began at $125 from New York or $97.50 from New Orleans. Traveling from New York to California for $200 and $300 for the round trip was possible. Tourism dropped during the Depression years of the 1930s and came to a halt during World War II. At the end of the war, United Fruit moved the basis of its operations from the Caribbean to the Pacific coast of Central America. They expected the company to contiue to accomodate passengers. This is despite the Great White Fleets unofficial motto. He said, “Every banana a guest, every passenger a pest.”

Advances In Technology In Transporting Bananas

Beginning in the 188os, technical advances in steamships, railroads, and refrigeration made it possible to transport perishable tropical merchandise such as bananas to all parts of North America. North America developed a nationwide network of railroads after the Civil War. This railroad network empowered farmers to transport their crops to seaboard cities and foreign markets. This network also facilitated the distribution of foreign products, including bananas, throughout the country. The railroads played a crucial role in connecting various regions and fostering economic growth. In 1885, a weekly cookery journal noted that the American people of this generation lived better than their fathers did.

The journal pointed to the steady and rapid growth of the trade in tropical fruits as one of the best pieces of evidence supporting this observation. Not many years ago, the great majority of people scarcely knew what a banana was. They considered oranges and lemons as luxuries. They thought to only buy them in sickness or on great occasions. Now people eat these tropical fruits as generally and freely as apples. The consumption of melons, peaches, pears, plums, and berries is on the same universal and extensive scale. This change tends to gratify the taste and promote health, which is the foundation of human happiness and is advantageous to everybody. Such are the facilities for rapid and safe communication from distant points that the world lays her tribute of sweet and sound fruits at the door of the enlightened nations.

Selling Billions Of Pounds Of Bananas

To sell billions of pounds of bananas to the people of the United States, the fruit companies had to establish wholesale and retail networks to move the fruit to the consumer. Profits lay in inefficient distribution, sales, and the total volume of fruit sold.

Farmers carefully harvest bananas. They wait for full development in the bananas. This is to withstand a journey of five to eighteen days before ripening to a yellow color with brownish flecks. Skilled individuals assess each banana’s condition during harvesting, ensuring that it meets the criteria for successful transportation.

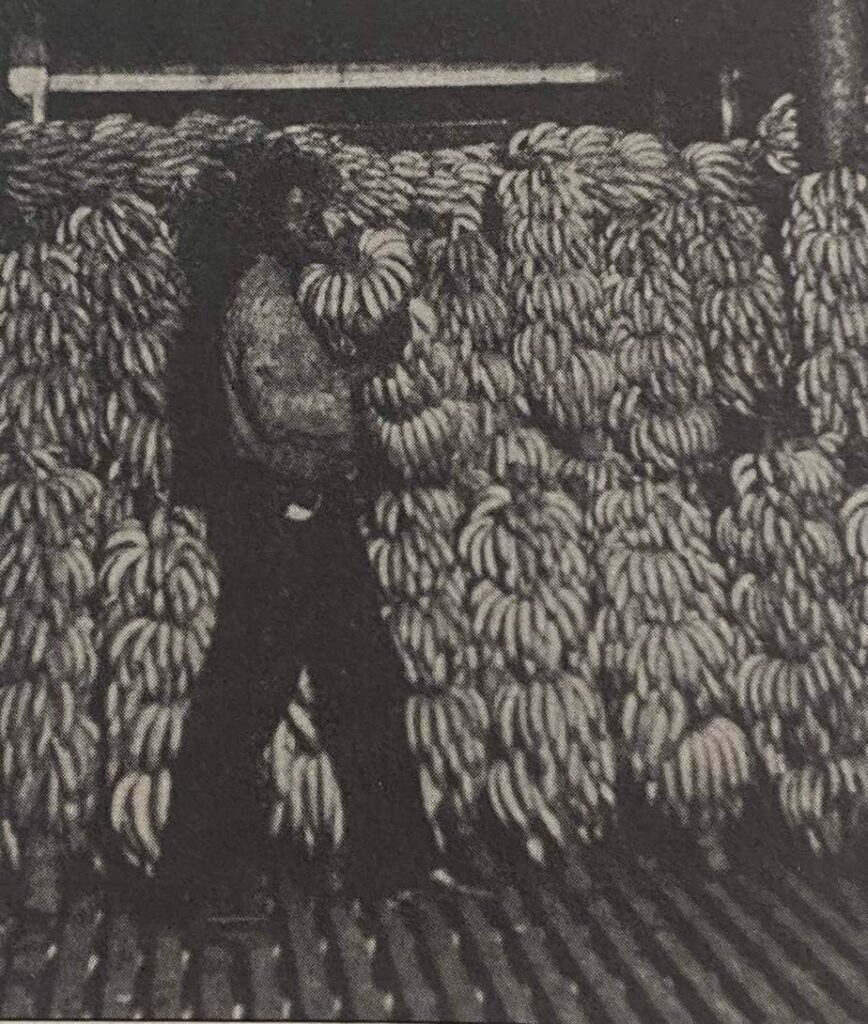

In the initial stages of banana transportation, workers hung the stems in tiers, installs, or boxes constructed of slats in the between-decks of steamers. They provided the optimal environment for air circulation. Later steamships with refrigerated holds kept the cargo at a temperature of 57°F to prevent the fruit from ripening too quickly on the voyage.

New Orleans As A Major Port In Banana Transportation

New Orleans was a logical port for the banana trade. It was the closest major American port to the Caribbean and the hub of an expanding railroad network that ran up the Mississippi River. A large market developed in the growing Midwestern cities and towns at the turn of the century. By 1905, New Orleans was the largest fruit-importing port in the world, distributing more than nine million stems of bananas by rail to the cities in the interior of the United States.

The first ventilated railroad car for transporting fruit resembled a large cage with iron bars, on the theory that the more ventilation, the better the fruit would “carry.” The Armour meatpacking company designed an improved slat-sided freight car. They made it quickly gained adoption for banana transport. In 1910, they dispatched over 60,000 freight cars, each containing 500 bunches, throughout the United States.

The Fruit Dispatch Company claimed it was the first to ship bananas under ice successfully. Responding to the refusal of storekeepers in certain sections of the country to handle bananas during the summer months, researchers undertook an experiment. The goal was to address the risk in transit and the storekeepers’ inability to sell the fruit without significant losses. The results of the experiment provided valuable insights into improving banana transportation and storage. By 1920, all companies had adopted ice to cool banana freight cars, and in the warm months of 1923, the southern division of the Fruit Dispatch Company alone used 29,731 tons of ice.

Freight In The Banana Business

One of the beauties of the banana business was that the freight moved inland from the port cities in the opposite direction to the bulk of other railroad traffic, making economical use of freight cars.

Banana trains comprised twenty to one hundred cars and maintained fast schedules. 49 In 1927, it took 55 hours for bananas to travel from New Orleans to Chicago, 88 hours to Minneapolis, 184 hours to Seattle, and 208 hours (nearly nine days) to Vancouver. They shipped the fruit to Cleveland, Detroit, and Toronto in about 36 hours. They shipped fruit from New York and Philadelphia ports.

The main line from New Orleans ran along the Mississippi River to Fulton, Kentucky, where five railroad lines met. Fulton became known as the Banana Capital of the World. At first, the Fruit Dispatch Company and other import companies sent “messengers,” often Italian, with each train to look after the perishable freight. Their job was to inspect cars and test the temperature of sample fruit by sticking thermometers into random bananas.

Weather Influence On Trade

According to the weather and condition, operators could ice the cars, heat them, or adjust the ventilation slats. By 1923, the company stationed resident messengers at strategic divisional and junction points. This was along the route, such as Fulton, Dubuque, Iowa, and Mounds, Illinois. They dispatched boxcars north, east, and west. Messengers and the men stationed at strategic checkpoints also reported. They reported to each other on existing and predicted weather conditions along the route.

Ice companies in New Orleans and at stops along the way supplied large blocks of ice. They inserted them into compartments at either end of the railroad cars during hot weather. The ice racks were elevated to prevent over-refrigeration of the bottom layers of fruit. Standard Fruit managed to buy up most of the ice plants in New Or-leans after 1915. Its President Joseph Vaccaro became known as the “Ice King.”

During cold months, workers papered the boxcars at the bulkheads and doorways, while also using straw to protect the fruit. To add an extra layer of precaution, one could use kerosene, oil, or charcoal heaters to warm the cars. In the northern ports, workers heated banana boxcars before loading them. In particularly cold weather, workers heated them again after loading the banana boxcars before sending them on their way. There were several large heating plants, one located at Rouses Point, New York, for shipments to Canada, one at Mounds, Illinois, and another at Dubuque, Iowa. The facilities in Illinois and Iowa were for shipments from southern ports heading north and northwest.

The Largest Freight Cars Built

The plant at Mounds was the largest and could handle seventy-two freight cars at one time. A large cooling and heating plant in Springfield, Missouri, built by the St. Louis and San Francisco Railroad Company, consisted of four tracks inside a shed. Each track could hold ten freight cars. Large air ducts crossed the roof of the shed, and canvas tubes carried warm or cool air into one end of the freight car and took it out at the other after passing through the fruit. Another peril of the shipping business was constantly changing regulations concerning disease in southern U.S. cities.

During a 1905 yellow fever epidemic that swept the ports of the Gulf Coast, the population faced significant challenges. New Orleans lost 452 lives. The widespread impact of the tragedy affected communities beyond New Orleans. Authorities imposed quarantines against ships from the tropics, often without notice, requiring a fifteen-day fumigation period. Dumping spoiled perishable produce, such as bananas, into the Mississippi River was particularly challenging during this time.

The public blamed epidemics on the fruit industry with its ties to the tropics. Specifically the Italians working on the ships and on the railroads in the United States. In the 1905 epidemic, the port of New Orleans refused to allow bananas to enter or leave the city.

Montgomery, Alabama, prohibited the entry of all bananas until frost. The town of Mounds, Illinois, asked the state board of health to prohibit the passage of banana trains. They feared that the messengers would infect them with yellow fever. Once the epidemic ended, the banana trade returned to normal.

After World War I, Americans began to demand better roads for the ever-increasing number of automobiles and trucks. Trucks had proven their worth during the war in Europe but needed an extensive system of paved roads. In 1921, Congress passed the Federal Highway Act, providing federal aid for state roads. In 1923, the Bureau of Public Roads began to plan a national highway system. By 1930, efficient truck services to small towns had first supplemented. This was ultimately supplanted the railway system in the United States.

The Origin Of Trucking For Bananas

Trucking began to affect a wide range of American life. It affected manufacturing plant locations to eating habits. More transport firms appeared to deliver goods to the expanding consumer-oriented society motivated by advertising. Truck routes could efficiently serve towns unserved by railroads. Bananas found their way into shops and stores even in small villages nationwide.

During the 1920s, authorities slowly expanded the road system. They haulted construction during the Depression until the authorization of the Works Progress Administration in 1935. Between 1935 and 1943, the WA was responsible for building over 650,000 miles of highways, streets, and roads. With the expansion of the road system, trucks began to compete with the railroads in regional and national markets. They changed distribution patterns, upset established markets, and opened new venues. Trucking, estimated to have brought the final 10 percent of the population with the national economy. This played a crucial role during this period. The extensive reach of trucking networks now connects these individuals. Major railroad arteries had previously isolated them.

Trucking Overtakes Rail For Banana Transportation

Refrigerated trucks began to compete with railroads for the banana business in the 1940s. Initially, grass and sawdust insulated trucks while barrels of water and ice cooled them. The refrigeration technology improved with the adoption of dry ice and later mechanical devices. One entrepreneur, Everett Lawrence, built up a fleet of thirty-four trucks to haul bananas. He hauled them to Midwestern markets previously supplied by rail. Trucking the fruit cost about half as much as by rail in the early 1950s. With this, the railroad banana freight business began to decline.

The Highway Act of 1956 dealt a severe blow to the railroads. The law resulted in constructing a 41,000-mile interstate highway system to assist commerce. This network connected all the country’s major cities and important industrial areas. It was fed by county, state, and national highways and provided a much more complete system than the railroads. Dried banana chips make shipping even easier.

Another advantage of truck transportation was that truckers charged flat rates. This was with no extra charges for loading, unloading, or refrigerating cargo. Railroads offered these services and arranged to cart small shipments to retail stores but charged extra for these services. Not all trucking was cheaper than rail transportation. The savings in time and the reduction in handling perishable goods often offset higher rates.

By the 1970s, fruit companies had largely abandoned freight trains. This is in favor of refrigerated tractor-trailer trucks to transport bananas to every hamlet and corner store in America.

Blog assisted by rzwilliams.com