Your cart is currently empty!

The Modern History Of Cashew Production

The cashew nut, Anarcadium Occidentale Linn is native to Brazil. From here, the tree spread to other parts of tropical South and Central America, Mexico, and the West Indies. The generic name, Anarcadium, was bestowed upon it because it described the heart shape of the nut. The specific name, occidentale, was used because the origin came from the Western and Southern Americas.

The large, spreading trees with milky juice is very sensitive to cold. The only place in the United States where they grow is the southern tip of Florida. The cashew plant is a jungle or semi-jungle tree by nature. The Portuguese introduced it into India and East Africa in the 16th century to help control erosion along the coastal regions of these countries. At this time, the nut was still not considered food by many.

How Cashews Can A Tree Produce?

The cashew tree grows with a minimum of attention and is easy for cultivation. A three-year-old tree bears an average of seven pounds of nuts. By the fifteenth year, trees average 70 pounds of nuts per tree. Mature trees of exceptional quality have yielded as much as 200 lb. In the history of cashew production, companies expect trees to produce nuts for 15 to 20 years. An occasional tree can go to a record of productivity for as many as 45 years.

Because of their spreading branches, cashew trees resemble large bushes. However, they are true trees and often reach 30 to 40 ft. They are evergreen and have recognition by their light-colored foliage. The yellow-green leaves, revealing distinct veins, are elliptic in shape and approximately 4 to 6 inches in length and 2 to 3 inches broad. They feel leathery to the touch.

J. F Morton, in 1961, reported the tree is susceptible to cold when young but becomes fairly hardy with age and is capable of withstanding short periods of light frost. It is highly adaptable to the soil, flourishing even in the sand of open beaches. The cashew tree grows poorly in heavy clay or limestone.

It is found from sea level to an altitude of 3,000 ft. and in regions with rainfall as high as 150 inches and as low as 20 inches. However, for maximum productivity, good soil and adequate moisture are essential.

Nut Varieties Grown During The History Of Cashew Production

There are, as yet, very few varieties named. Generally, a distinction is made only between those with yellow or red cashew apples. Tests have indicated that huge nuts usually have inferior kernels, are of low density, have poor vitality, and have slow germination.

Harvesting

The path of the cashew nut from harvesting to importation is interesting. Cashew trees bloom in India in mid-December and bear flowers until early February. In March and April, the cashew “apples” are ripe, and the main crop of nuts is ready for harvesting. Some trees yield a ripe malt crop in October and November. Harvesting periods differ seasonally in other cashew-growing countries like Vietnam and Brazil.

After the nuts are gathered, they are sun-dried for two days. The moisture content is thus reduced from 16% to 7% so that the nuts can be safely stored. The nuts may either be bagged and held for future processing or immediately processed, graded, and packed for export.

Ripe fruit is not plucked from the trees but falls to the ground and is picked up by the natives. Either by hand or automated equipment. The whole nuts will remove from the fruits by a small hand tool and then soak in hot water. A small percentage of the “apples” is shipped to the market for local consumption. Most of the fruits are not utilized. The history of cashew production shows many businesses trying to find a use for the cashew fruit after the cashew nut is removed. There are possible consumer products and industrial uses.

Preparing the cashew kernels for export is more intricate than preparing other edible nuts. They are cleaned, processed to remove the oily shell liquid, “cracked” to liberate the kernel, dried to facilitate dehusking, “peeled” to remove the testa, graded, and packed in compliance with the rules of the Indian Cashew Export Promotion Council.

The Cashews Had One Single, Dramatic Price Increase in 1966

The pressure of a smaller 1966 crop of cashews in India and Eastern Africa. Down 10,000 short tons from the 90,000 tons in the 1965 crop in India. Contributed to substantial price increases in both the kernel and raw nut markets. That was the most significant price increase in the entire history of the cashew. Even during the challenging years of shipping cashews during the covid crisis, their price did not change much.

Another contributing factor to a rising nut market was the increasing competition from mechanized East African shelling industries for raw nuts. This became a significant factor first during the 1966 season in the history of cashew production. The cashew kernel market received an additional boost from the sharply increasing demand for shelled cashews, particularly from the USSR. Russian purchases rose from 10,000 short tons in 1963 to nearly 15,000 tons in 1965.

The main issue with studying cashew imports and exports from this era is the total tonnage. See, in the 50’s, 60’s, and 70’s, changing product that was exported. Countries would import the cashew seed inside of the fruit. So, they do not account for the tastes changing for the cashew nut over time. In America, we have all but stopped importing cashew fruit. Today, we only import bulk raw cashew seeds and bulk roasted and salted cashew seeds.

Processing Improvements In The History Of Cashew Production

The first step in preparation is cleaning the shell. Whole raw nuts are passed through rotary cleaners to remove any foreign substance that adheres to the outer surface. They are then washed in a water bath and stored in moist heaps or silos for 12 hours to make the shells brittle. Moisture is maintained at 7 to 10%, at which range the cells within the shell readily rupture, liberate the oily shell liquid, and retain it within the shell.

The nuts are now ready for processing to remove the shell liquid. Significant advances have taken place in this process. Years ago, this was performed by crude native methods. Whole raw nuts were roasted in open, roasted charcoal fires. Constant agitation is required during the roasting to reduce the scorching of the nuts.

The Challange Of Roasting Cashews

Roasting by this method was dangerous and disagreeable. The shells burst, spurting the caustic liquid and releasing clouds of acrid fumes shells blistered the skin and irritated the workers. At the same time, the shell liquid would dissipate.

Methods were improvised to salvage the oil by roasting the nuts in perforated pans. Catch troughs were placed underneath to collect. About one-half of useful material would recover with this innovation. In the history of cashew production, the problem of irritation from the oil and its fumes will always be an issue

Cashew Shell Liquid Became Valuable

Processing equipment was improved to make roasting safe and to recover the shell liquid. Furnaces fitted with chimneys that transfer and discharge the acrid fumes are used as a controlled heat source. The whole nuts are placed in large perforated cylinders. Subsequently, rotating at an angle above the heat source. As the nuts travel down through the rotating cylinders, the shell liquid flows through the holes in the cylinder and is captured in the catch troughs. When the roasted nuts emerge, they are water sprayed and set aside to cool and dry.

Some of the giant factories are introducing still more advanced processing methods. Whole nuts are being treated in oil-bath tanks maintained at 370-380° F. to remove the shell liquid. Vents or flues connected to the tanks dispel the troublesome fumes, and the equipment recovers 85% to 90% of the liquid.

A steam process for treating whole raw nuts has a patent. If adopted, it may have an added advantage in that it claims to produce a better grade of cashew shell liquid.

The hand “cracking” results in many broken kernels, which bring a lower market price. A machine has recently started operation in Tanganyika. It removes the shell and keeps the kernel intact. The machine operator covers his hands with a coating of cream to protect them from the vesicating action of the shell liquid. He places the nut in a gripper which moves against a circular saw. This cuts a groove into the shell. A bladed implement inserted within the groove removes the kernel like the “shucking” process used to open an oyster. Machine “crack-ing” has upped production, and a worker now opens from 600 to 1,000 nuts per without breaking the kernels.

Processing Methods To Create Cashew Shell Liquid

Nut “cracking” was the manual work of Indian women and is currently the work of both genders. Squatting on the floor with a small bowl of lime, ash, linseed, or castor oil beside them, they place the nut on a hard stone and “crack” the shell by hitting it with a wooden mallet. The kernel then separates from the shell. During the shelling, the workers protect their hands by dipping them into the bowls to wash away any traces of the oily shell liquid.

The cashews may be roasted when raw kernels have the shell taken off. Commercial roasters use metal trays over a coal furnace in olive oil or peanut oil. When roasting is half complete, they will remove and put in a mix with a small amount of liquid paraffin. Replaced on the tray and given another five-minute roasting, sprinkled with salt, gum acacia, and water, and finally reheated to remove excess moisture.

In India, the estimation is that 250,000 tons of cashew nuts would grow in each harvest annually during the sixties and seventies. 85% of the crop goes to waste. Of the 15% utilized, some are fed to swine.

After “Cracking,” the nuts get put in an industrial drier, and the resultant moisture reduction causes the kernel’s shrinkage. Removing the reddish-brown testa surrounding each kernel becomes a simple “Peeling” operation, and kernel “peelers” quickly and easily remove the loose, thin membrane-like pellicles. If the kernels are to be held in storage, this “Peeling” procedure may be held off. Subsequently, they receive a grade to help retain the freshness of the nuts.

Grading

“Garblers” grade the kernels according to sizes, shapes, and characteristics described and defined in grading schedules. These schedules, drawn up by The Cashew Export Promotion Council in 1962 in India, are known as “The Cashew Products Export Grading and Marking Rules.” Under these grading rules, six schedules are established. Each schedule species the grade designation, trade name, number of kernels per pound for whole kernels, a description if necessary, and the general characteristics of the quality of kernels within the group.

There are no U.S. Standards for Grades for cashew nuts. Why? Because America does not grow cashews for export. In other countries, grade designations will break down into these five categories:

- Whole scorched cashew kernels,

- Whole dessert cashew kernels,

- White cashew Kernel pieces,

- Scorched cashew kernel pieces

- Dessert cashew kernel pieces.

On April 1, 1963, a “Quality Control Scheme for Cashews” became effective in India. Under this plan, qualified entomologists inspect cashew factories and advise management on necessary preventive and remedial measures to ensure proper plant sanitation. The entomologists also supervise special anti-infestation control measures such as insecticide spraying and fumigation with methyl bromide as a protective measure when necessary.

India believes that the new “Quality Control Scheme for Cashews” will improve the reputation of cashew nuts in foreign markets.

The Cashew Export Promotion Council of India has introduced a compulsory pre-shipment inspection and quality control system. Under this system, only packers with modern factories equipped with all processing facilities are certified as authorized packers. They must strictly follow the rules relating to processing and packing and keep their factories in a perfect sanitary condition. This vigilant quality control has yielded good dividends in the shape of increased reputation and demand for Indian cashew nuts in foreign countries.

Weevil Infestation Is A Challange Even Today

Weevil infestation was a constant problem when the United States started importing cashew kernels shortly after World War 1. Spoilage caused importers to sustain heavy losses, and interest in the nut declined. In 1923, consumption in this country was a mere 100,00 pounds. Then the first significant breakthrough to control infestation occurred. Owing to this process of hermetically sealing the metal shipping container and replacing the air with carbon dioxide, infestation decreases significantly. From this point on, imports into the United States rapidly expanded. Later was the introduction of the vacuum pack process, and shelf life would have consideration for even longer weeks and months. Granting the farmers more time to get their products to customers in cold climates. Researchers consider this revolution from 1923 to 2023 to encompass the modern history of cashew production.

Only new, clean, dry-leak-proof tins may be used to pack the kernels. The containers must be free from insect infestation, mold, and rust. Four-gallon tins of 25-pound net weight capacity are the sizes for bulk exports. Except that white Baby Bits may be in packs of 28 pounds into the tin.

When kept under proper storage conditions, cashew kernels show little or no deterioration in quality. They may safely store in a warehouse for use throughout the year. Although the kernels are vacuum packed, they require cold or “cool” storage below 48° F. Below this point, an insect’s life remains dormant.

Consumers That Enjoy The Fruit And The Seed

The cashew has a fruit-like stalk called the “cashew apple”. The nuts are stripped from the plant and processed for their kernels and the increasingly essential oil from the shells. The deliciously juicy “apple” is little known outside the tropics. Indeed, it is thin-skinned and will therefore spoil quickly. The extraction and concentration of the juice that customers actually enjoy would change the entire future history of cashew production. If a juice market could be developed, the crop harvested for nuts is already available. Indian cashew apple wine and chutney are leading products, but the rest of the fruit is eaten locally, used for cattle feed, or wasted.

Most fruit contains seeds within the pulp or fleshy part of the fruit. This is not so with the cashew. The nut is on the outside of the pulp and is located at the distal end of the fruit, the point furthest away from its attachment to the stem. This unusual location of the nut gives the fruit an exciting and unique appearance.

The cashew “apples” or “pears” are displayed at local bazaars. They are succulent. A sweet acid flavor. In the tropical Americas, where they are grown, the native population is fond of them. Brazilians rate the fruit highly. Thus in some parts of the West Indies. and the tropical Americas, the nut is thrown away with the “apple” or “pear” and is considered a delicacy. They are eaten raw or cooked and prepared into a jam or preserve. The fruit juice is fermented and made into wine by the people of Brazil, Portuguese East Africa, and other counties.

The Cashew Beverage Makes A Comeback

In 2022, The National Institute Of Technology Karnataka patented a process for turning cashew fruit into a beverage. Karnataka, India, is the largest cashew-producing country. This might turn cashew into an ingredient that becomes popular worldwide. As a result, for nearly 100 years, producers have tried to find worthwhile ways to recycle the fruit surrounding the valuable cashew seed.

Eighly-five percent of this crop exported in the 1970s became waste. Part of the remaining 15% has a use as pig feed. Because it is highly perishable, even when held in vials at cold storage temperatures, researchers are seeking new methods to extract and process the juice. Testing new formulations which it may incorporate.

The fruit and wine, rich in vitamin “C,” possess antiscorbutic properties. Years ago, the liquor has value for its diuretic properties. Thus the claim is that there is a beneficial effect on the kidneys and will prescribe in advanced cholera cases. The treatment of cholera patients with caustic cashew skin has been in use for many years over the history of cashew production. Altogether, I have not found any evidence in the research to back this up.

Cashew Shell Liquid

Cashew shell liquid is highly caustic and is a potent vesicating agent. Such blistering action to the skin precludes importation. Also, the retail sale of unshelled cashew nuts is restricted. Proof of this is many governments have had to restrict the exposure of this harmful liquid to the public in the modern history of cashew production

A study done between 2010 and 2014 finds that raw cashew apple juice is prescribed for stomach disorders. Given to arrest vomiting and has a use as a gargle for sore throat. Since fresh or after distillation, the juice benefits for patients with uterine complaints or dropsy.

Skin Irritation Caused By The Cashew Fruit Is Similar To Poison Ivy And Poison Sumac

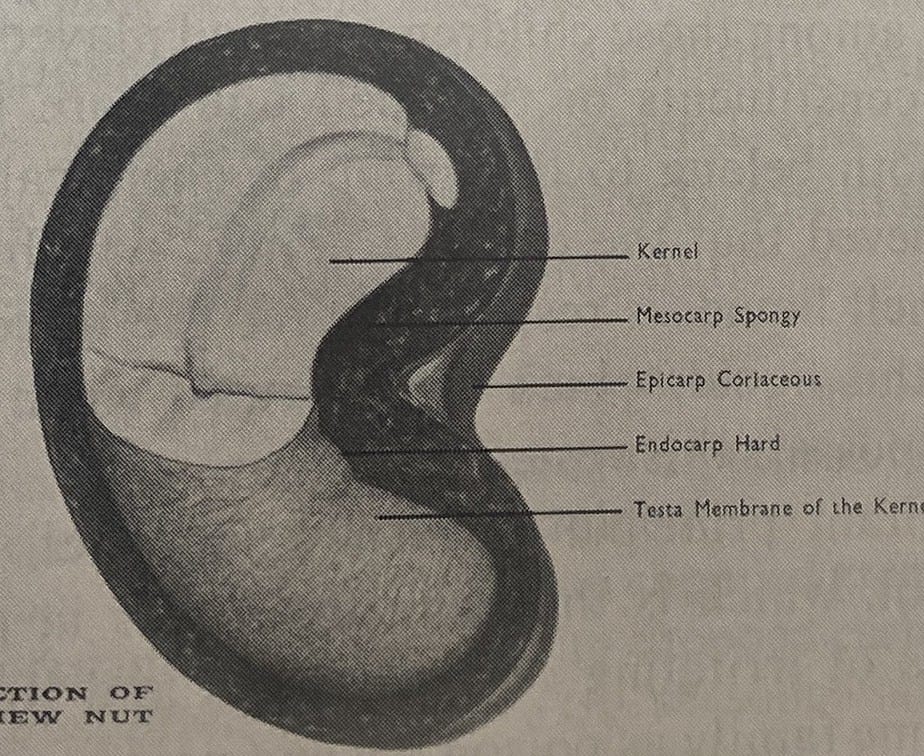

With this in mind, the double shell contains a toxic liquid that comprises 70% of the cashew nut. Consequently, the liquid contents are very toxic and irritating, producing blisters on the skin similar to those caused by poison ivy. Before being shelled, the nuts are heated in cashew nutshell liquid to make the shells brittle and extract the toxic liquid. This liquid or oil is not confused with many industries’ fatty oil recovered from the kernel.

The Department of Health of New York City recently encountered whole-brown cashew nuts carved into doll-like heads. They would attach to the ends of sticks and find use as souvenir novelties. Although this Department discovered no cases of skin irritation, it stopped the distribution of the cashew dolls as a precautionary health measure. In 1958, the United States Public Health Service confiscated a similar doll stick. Owing to the improper preparation of the whole cashew nuts, which had been done in the roasting. The shell liquid had seeped through openings in the cashew shell and caused a rash among those children who had played with them.

The principal constituents of the shell liquid are the chemicals Cardol and Anacardol. Both belong to the group of chemicals classified as higher phenols. The current belief is that the cardol fraction, which comprises about ten percent of the shell liquid, is responsible for the significant irritant properties. The fumes from this liquid, which liberate when the shells have exposure to heat for cracking, also possess this vesicating action.

Cardol, the irritant principle in cashew nut shell liquid, is a chemical relative of urushiol, the aggravating factor in poison ivy. Both produce similar irritating skin reactions; thus, the cashew tree is classified in the same family as poison ivy and poison sumac.

Economic Uses Of The Cashew Shell Liquid In The History Of Cashew Production

Undoubtedly, cashew shell liquid makes several types of resins, which have use to manufacture varnishes. Therefore, frequent skin irritations afflict the workers. Further, there is a record similar to if they handle raw cashew fruit. For this reason, there have been studies from case histories of workers who had contact with the resins or varnishes.

The cashew nut shell liquid is second only to the cashew kernel or nutmeat in economic importance. In its natural state, it protects the kernel against insect attack. Evidently, when combined with kerosene or diesel oil, it is an effective insecticide against mosquito larvae. Consequently, it will have an industrial use when it becomes an ingredient in a varnish. Working as a preservative of wooden floors and finely carved woods, protecting them from insect destruction. For this reason, fishermen have used the liquid to waterproof and preserve their fishnets, fishing lines, and boats.

Indeed, with recent advances in chemical technology, shell liquid is finding many new industrial applications. It is now a helpful material in manufacturing paints, plastics, printing inks, insulating varnishes, wood preservatives, waterproofing compounds, and synthetic resins. Hence, cashew resins find uses in manufacturing brake linings and clutch facings, which possess excellent frictional properties and low frictional fade. The resins are proving worthy as laminating agents for papers, clothes, and glass fibers. They have a use for treating cement floors subject to chemical attacks. Surprisingly, they have a use in some synthetic rubbers to protect them against aging.

In conclusion, many technological developments in the past few years are resulting in the fast growth of the cashew shell liquid industry. India is currently producing 6,000 to 7,000 tons annually of exportable shell liquid. Consequently, new industrial applications are considerably increasing the annual tonnage exported